Please read the complete article:

http://benchtopmachineshop.blogspot.com/2017/04/mill-vises.html

After using my screwless vise for over half a year I've become kind of fed up using it as my everyday vise. The hassle of adjusting it to hold different parts and trying to re-position the jaw constantly interrupted and slowed down the work. The modifications I made had improved it, but not enough.

I ended up getting a 3" Kurt-style milling vise. The Kurt-style vise forces the moving jaw downward as it's tightened, which keeps the part from lifting. While it's not quite as precise as the screwless vise, it is a lot nicer and faster to use. If I need the extra precision I'll just mount the screwless next to it.

The first thing I did was take it apart and clean it up. It turn out the casting for the jaw where it meets was the nut was deformed with extra material in the jaw. Using my Dremel I cut away the extra. Also with the Dremel I smoothed out the location where the hemisphere rides in the jaw. After this I lubed it up and reassembled it.

At the end of the day if I could only have one vise I'd go with the screwless vise just for its precision and multiple ways of mounting it.

Wednesday, February 25, 2015

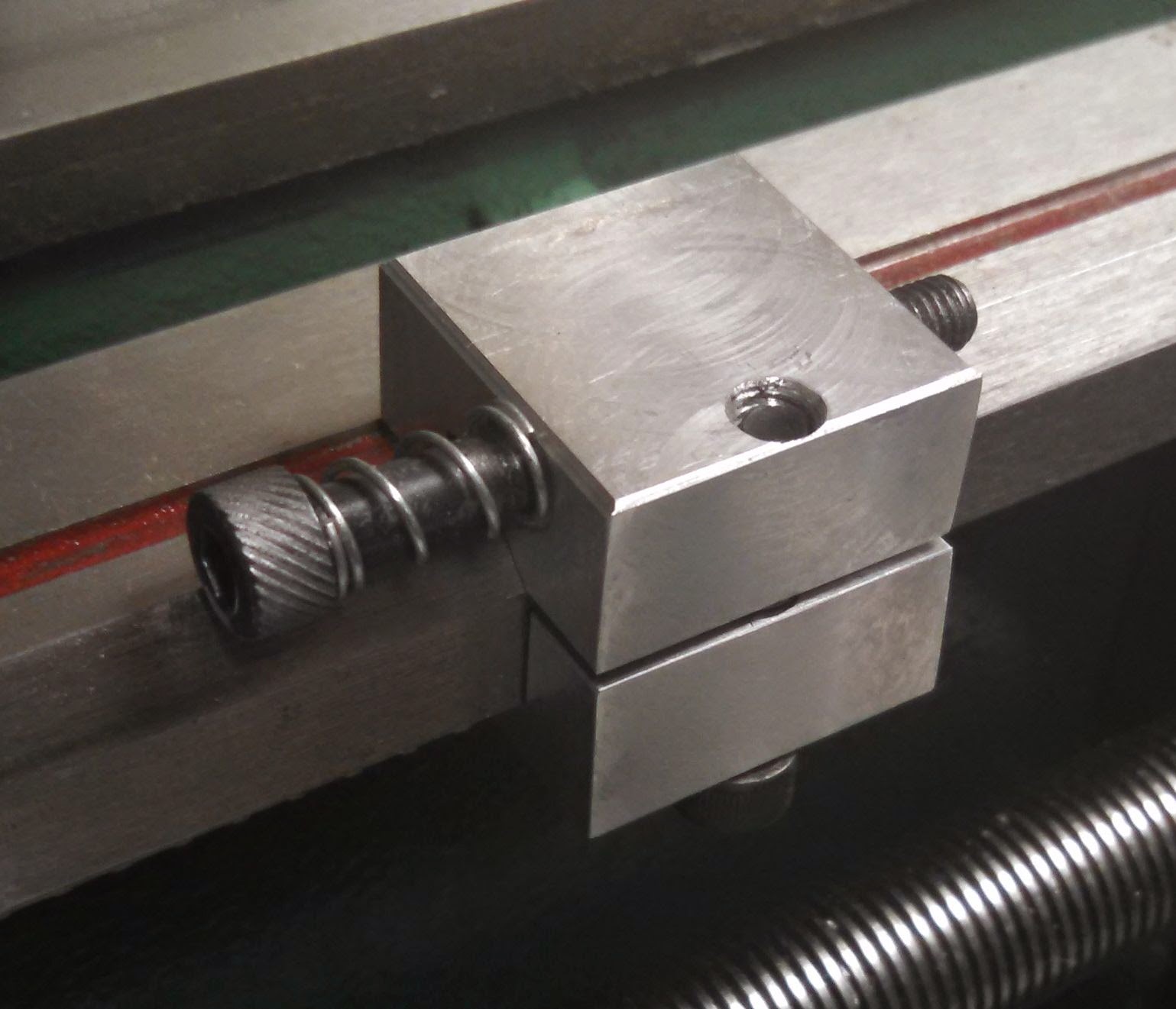

Lathe: Carriage Stop

Decided to make a carriage stop for the lathe. Even though I have the DRO, it's nice to just move the carriage until it stops instead of to a number. It was just made from aluminum, and the screw to tighten it was moved to the bottom so it wouldn't interfere with the ways protectors I have installed. Currently you need an allen key to tighten/loosen it, and I probably won't change that since I don't see myself using it all that much.

Lathe: Compound Lock and Gib

The compound slide gib is not nearly robust enough for the forces you can see, especially when parting and threading. I've seen the whole compound rotate over on the gib when the parting blade jammed. To remedy this I added to both add a gib lock and to add an extra gib set screw.

I removed the top of the compound and clamping it in the mill and drilled and tapped two extra holes located exactly between the existing set screws. After modifying the gibs (http://benchtopmachineshop.blogspot.com/2015/01/lathe-gibs.html) I put a dog nose on a M4 SHCS and installed it in the middle set screw hole. Now the compound has more support overall and I can easily lock it in place.

I removed the top of the compound and clamping it in the mill and drilled and tapped two extra holes located exactly between the existing set screws. After modifying the gibs (http://benchtopmachineshop.blogspot.com/2015/01/lathe-gibs.html) I put a dog nose on a M4 SHCS and installed it in the middle set screw hole. Now the compound has more support overall and I can easily lock it in place.

|

| Extra gib set screws with the gib lock right in the middle. |

Monday, February 9, 2015

Mill: Screwless Precision Vise

Please read the complete article:

http://benchtopmachineshop.blogspot.com/2017/04/mill-vises.html

One of the biggest annoyances using the precision screwless vise was loosening the jaw and accidentally unscrewing it from the T bracket which holds the cross bar that hooks into the base. After having it happen it again in the middle of a project I took the screw which connects the jaw to the T and turned it smooth starting 5 threads from the end.

I then ground a flat on the T right where it threads onto the screw. I then assembled the vise, threaded the screw into the T, and peened the flat to capture the screw. Now, no more accidentally unscrewing it.

http://benchtopmachineshop.blogspot.com/2017/04/mill-vises.html

One of the biggest annoyances using the precision screwless vise was loosening the jaw and accidentally unscrewing it from the T bracket which holds the cross bar that hooks into the base. After having it happen it again in the middle of a project I took the screw which connects the jaw to the T and turned it smooth starting 5 threads from the end.

|

| Middle section of screw turned smooth. |

I then ground a flat on the T right where it threads onto the screw. I then assembled the vise, threaded the screw into the T, and peened the flat to capture the screw. Now, no more accidentally unscrewing it.

Wednesday, February 4, 2015

Bandsaw Vise

I wanted to add a bandsaw to my workshop, but because of limited space I needed something small. The Grizzly G8692 portable bandsaw and stand were the right size and definitely the right price.

The big problem was the included vise. It was too flimsy and stood way too far away from the blade. If you're never cutting a piece less than 12" long it might work, but it's utterly useless cutting anything short.

The first thing I did was move the vise toward the saw by 1.5". That's as close as I could get it without the saw hitting the vise. At this distance the saw cuts slightly into the vise base, but that's fine. The vise's quick release lever needed to be slightly shortened so it wouldn't interfere with the saw. The bolt also interfered with the saw so I switched it out for a socket head cap screw on which I turned the head down to a smaller diameter.

Then I cut sections of 2" wide 1/8" steel plate to extend the vise jaws all the way to the edge of the saw blade. In addition, the fixed saw got an extra 1/8" plate bolted to its back to help stiffen it more. The plates and jaws were welded together at their edges. A brace was also added between the fixed jaw and the base.

Since the moving jaw on the bandsaw vise is on a pivot, if what you're clamping doesn't extend beyond the pivot, the whole jaw will rotate and won't clamp. To fix this I drilled a 1/2" hole in the fixed jaw on the end of the vise opposite the saw, and welded a 5/16" nut to the outside of it. I then took a piece of 5/16 threaded rod, red Loctited two nuts onto the end, turned the other end flat and chamfered it, and then threaded it through nut. Now I can quickly thread the rod through to space the moving jaw correctly.

It's still not perfect, but it's very usable now.

The big problem was the included vise. It was too flimsy and stood way too far away from the blade. If you're never cutting a piece less than 12" long it might work, but it's utterly useless cutting anything short.

The first thing I did was move the vise toward the saw by 1.5". That's as close as I could get it without the saw hitting the vise. At this distance the saw cuts slightly into the vise base, but that's fine. The vise's quick release lever needed to be slightly shortened so it wouldn't interfere with the saw. The bolt also interfered with the saw so I switched it out for a socket head cap screw on which I turned the head down to a smaller diameter.

Then I cut sections of 2" wide 1/8" steel plate to extend the vise jaws all the way to the edge of the saw blade. In addition, the fixed saw got an extra 1/8" plate bolted to its back to help stiffen it more. The plates and jaws were welded together at their edges. A brace was also added between the fixed jaw and the base.

|

| 1/8" steel reinforcing plates welded into place. |

|

| Brace welded in place. |

Since the moving jaw on the bandsaw vise is on a pivot, if what you're clamping doesn't extend beyond the pivot, the whole jaw will rotate and won't clamp. To fix this I drilled a 1/2" hole in the fixed jaw on the end of the vise opposite the saw, and welded a 5/16" nut to the outside of it. I then took a piece of 5/16 threaded rod, red Loctited two nuts onto the end, turned the other end flat and chamfered it, and then threaded it through nut. Now I can quickly thread the rod through to space the moving jaw correctly.

|

| Threaded rod in place, screwed all the way out. |

|

| Threaded rod adjusted in to space the moving jaw. |

It's still not perfect, but it's very usable now.

Subscribe to:

Comments (Atom)